Salient Features Of Laser Welding

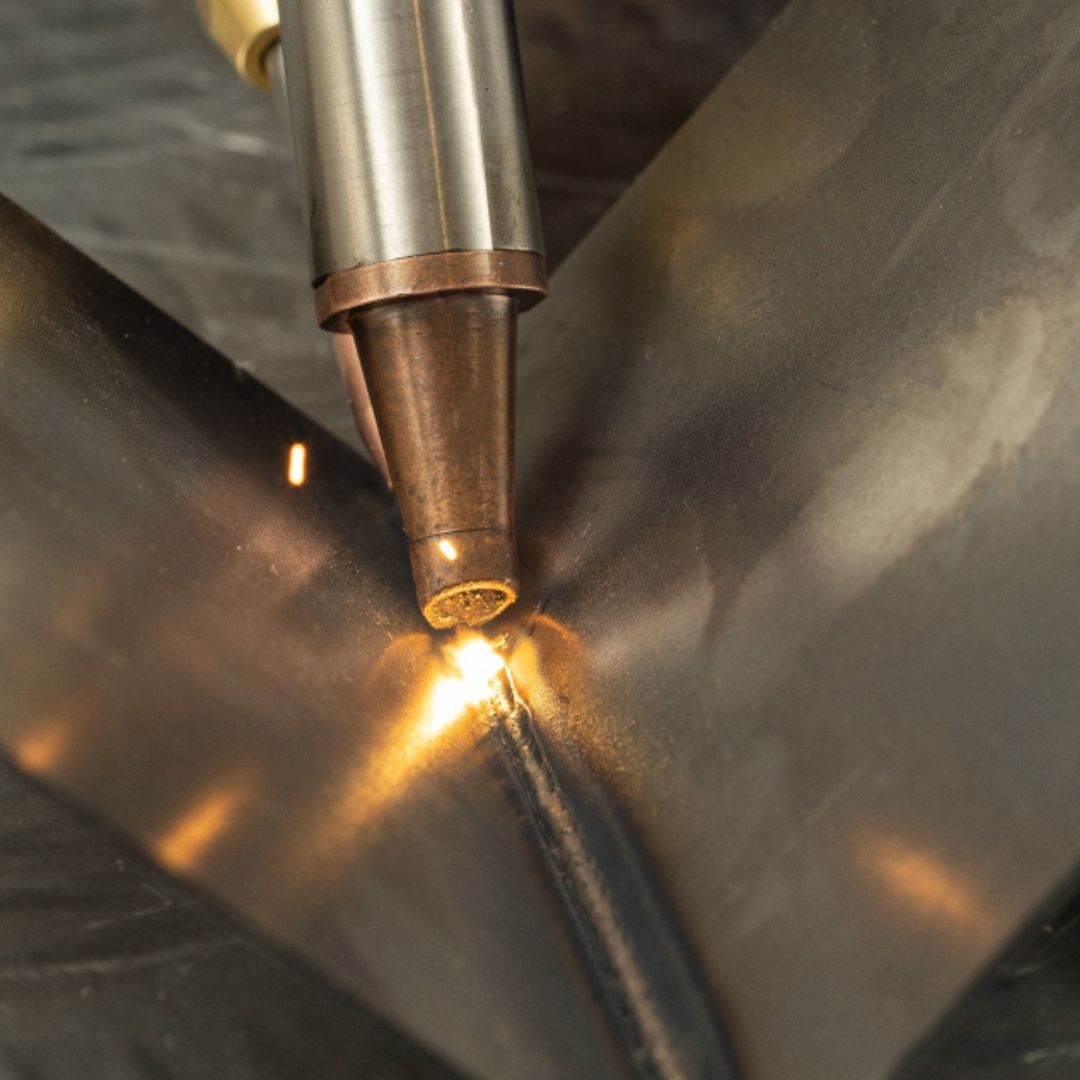

Laser welding, a cutting-edge technique in the world of welding, has gained popularity due to its precision and efficiency. Unlike traditional welding methods that use heat from an open flame or electric arc, laser beams are employed to generate intense heat at the desired spot. This concentrated energy melts and fuses metal components with remarkable accuracy.

The process begins with a high-powered laser beam being focused onto the surface of the material being welded. The laser's energy is quickly absorbed by the material, creating a small molten pool that solidifies upon cooling. What sets laser welding apart is its ability to produce narrow and deep welds without excessive heat input.

Perks of Laser Welding

1. High Precision and Accuracy:

When it comes to welding, precision and accuracy are crucial factors that can make or break the final outcome. Traditional welding techniques often struggle with maintaining precise control over the heat input, resulting in inconsistencies and flaws in the welds. Using a highly focused laser beam, laser welding generates intense heat at a specific point on the material being welded. This concentrated heat source allows for pinpoint accuracy during the welding process. The narrow weld zone produced by the laser ensures minimal distortion and reduces the chances of damage to surrounding areas.

2. Minimal Thermal Distortion:

Minimal thermal distortion is one of the standout features of laser welding that sets it apart from other conventional welding techniques. When traditional methods are used, intense heat is applied to the entire workpiece, resulting in significant thermal expansion and distortion. However, laser welding utilizes a concentrated beam of light energy to melt and fuse the materials.

3. Versatility in Material Compatibility:

When it comes to welding, one of the biggest challenges is finding a technique that can work with various types of materials. This is where laser welding truly shines! With its exceptional versatility in material compatibility, laser welding offers a solution for joining different metals and alloys with ease.

4. Faster Processing Speed:

One of the key reasons why laser welding is so fast is due to the concentrated heat source provided by the laser beam. The intense heat generated allows for rapid melting and bonding of materials. This means that welds can be completed in a fraction of the time compared to other methods.

Metal Tronics Inc. uses the latest technology and machinery to serve our clients for laser welding in Toronto and laser cutting in Mississauga, Ontario.