Steps Involved In Fabrication of Sheet Metal

Fabrication of sheet metal is a process used to create items from sheet metal stock. It involves cutting and forming the material into various shapes and sizes. Sheet metal fabrication is used in a variety of industries, including aerospace, automotive, and medical device manufacturing. This blog post will cover all the steps involved in sheet metal fabrication in detail. From design to production, let’s take a closer look at what makes up this complex manufacturing process.

The process of fabrication of sheet metal

Cutting:

The first step is cutting the metal sheet to the desired size and shape. This can be done with a variety of tools, including a saw, shears, or a plasma cutter. Laser cutting is also one of the most used techniques in this step.

Bending:

The process of bending sheet metal is a common fabrication technique that is used to create objects with curved surfaces. There are a variety of methods that can be used to bend sheet metal, and the choice of method will depend on the type of material being used, the desired shape of the finished product, and the available equipment.

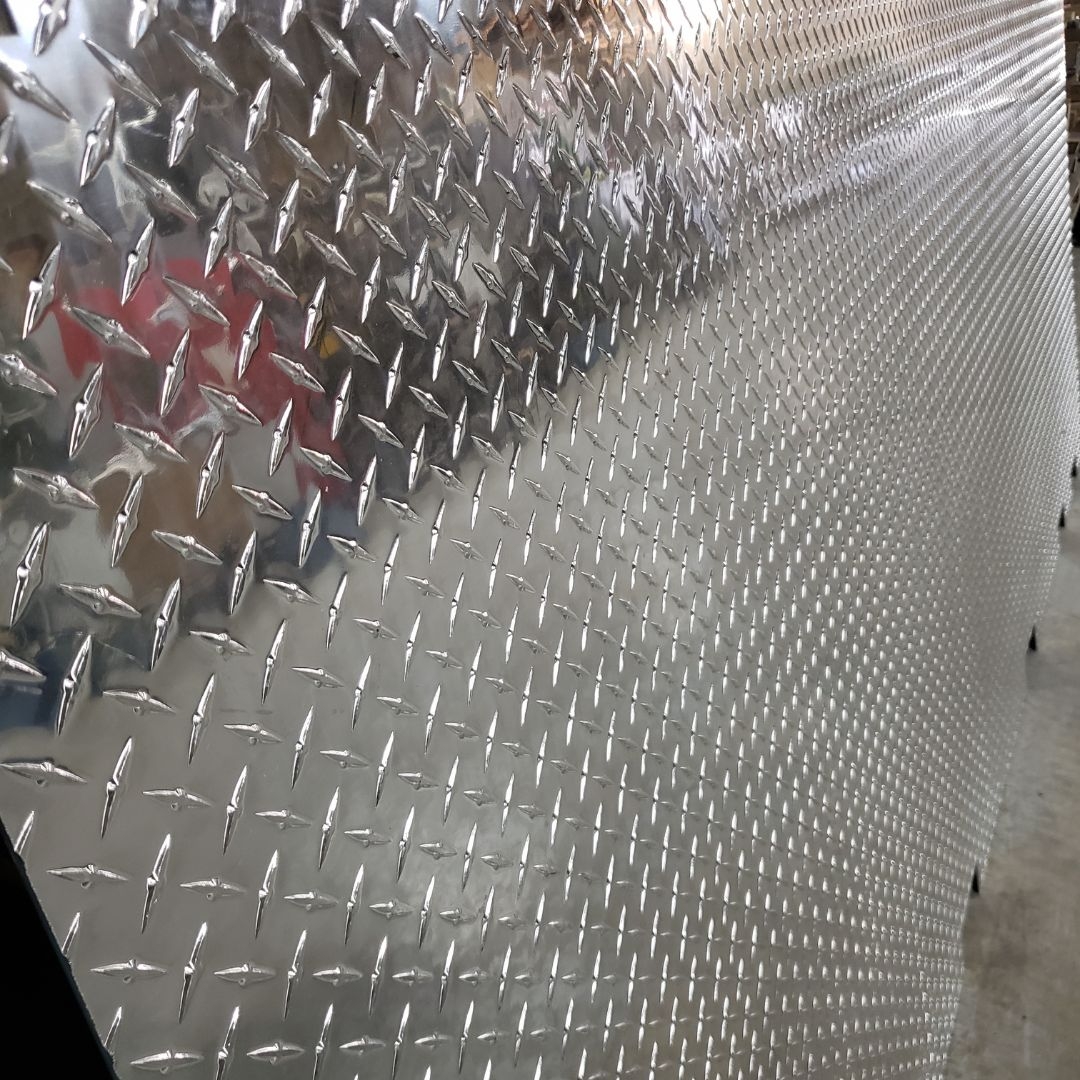

Forming:

Forming is the process of shaping a piece of sheet metal into its desired form. There are many different ways to form sheet metal, but the most common method is by using a die. A die is a tool that has a negative shape of the desired part. The sheet metal is placed over the die and then struck with a hammer or press to force it into the shape of the die. Other methods of forming sheet metal include bending, stretching, and stamping.

Welding:

There are various welding processes available for sheet metal fabrication, and the best process to use will depend on the materials being used and the desired results.

Finishing:

After the sheet metal has been cut to size, it's time to finish the edges. The most common method of finishing sheet metal is to use a power sander. This will remove any burrs or sharp edges and give the metal a nice, smooth finish.

Consult with our experts at Metal Tronics Inc. for a professional service. Talk to us today!