Why Manufacturers Prefer Metal Laser Cutting Today

Today's fast-paced manufacturing world demands precision, efficiency, and versatility. The metal fabrication industry has undergone several revolutionary advancements in recent years to meet the ever-increasing demands of manufacturers. Among them, the metal laser cutting process stands out. It is a reliable technology that provides manufacturers with numerous advantages. Metal Tronics Inc., Mississauga, Ontario, sheds light on the popularity of this process among manufacturers via this blog.

What Is Metal Laser Cutting?

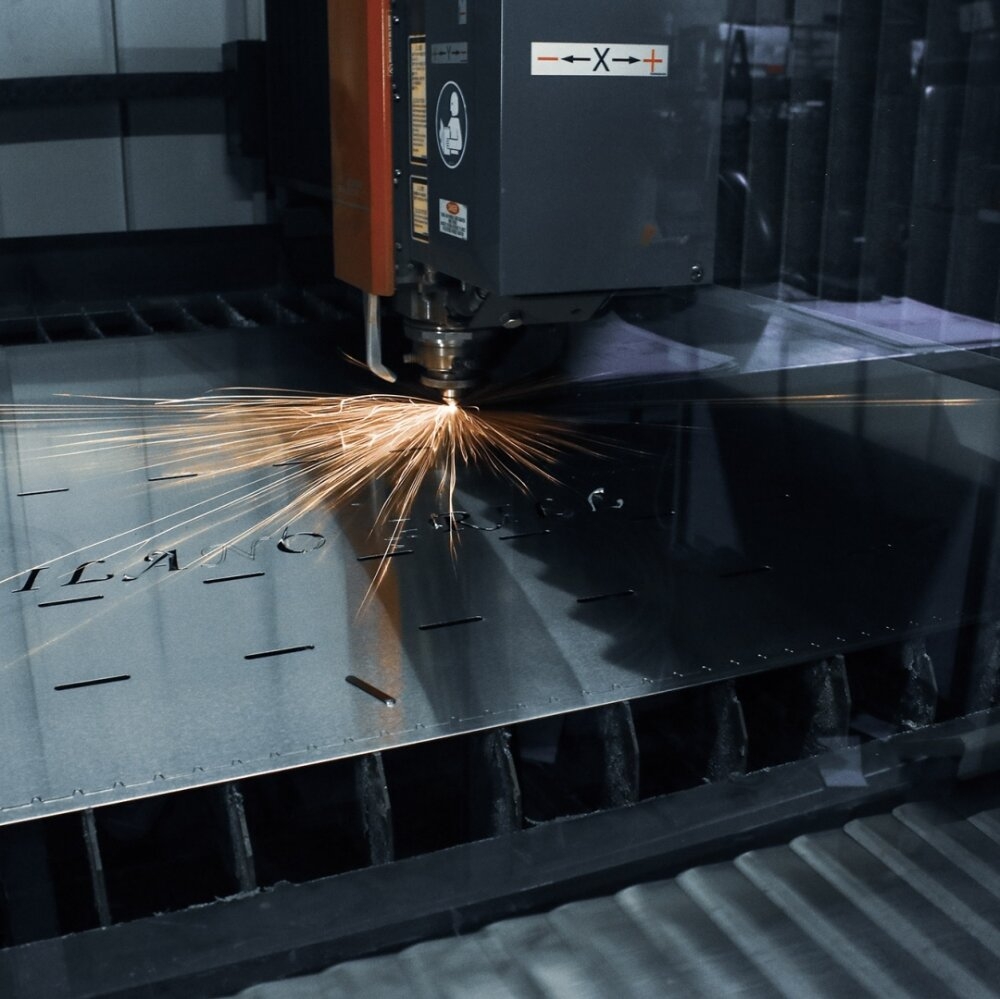

Metal laser cutting is a technology that uses a concentrated laser beam to cut through metal with extreme precision. The process involves directing a high-powered laser onto the metal, melting or vaporizing the surface along the designated path. It is purely a computer-controlled method. Metal laser cutting can be applied to a wide range of materials like steel, aluminum, brass, etc.

Why Do Manufacturers Prefer Metal Laser Cutting?

Metal laser cutting combines speed, precision and cost efficiency. Here's what makes it invaluable to the manufacturers.

- Unmatched Accuracy: Computer Numerical Control (CNC) ensures every cut is precise, even on the most complex designs.

- Minimal Material Waste: The narrow cutting width reduces scrap, optimizing raw material use.

- Smooth Finishes: Clean edges eliminate the need for additional finishing, saving both time and cost.

- Speed and Efficiency: Laser cutters work faster than traditional saws or plasma cutters, enabling quicker project completion.

- Versatility: It can handle a wide range of metals and thicknesses, making it ideal for diverse industries like automotive, construction, and electronics.

How Does Metal Laser Cutting Improve Manufacturing Quality?

Consistency is metal laser cutting's strongest suit! Every cut, bend and corner meets the exact design specifications. Uniformity results in time saving, less material wastage, quick turnaround time and faster operation. This means more business and more money. Additionally, the non-contact nature of laser cutting minimizes human error and mechanical stress on the metal, preserving its strength and integrity.

Why Choose Metal Tronics for Metal Laser Cutting?

Metal Tronics Inc. has been in the business for over four decades. With an advanced CNC laser cutting system and highly skilled technicians, our precision meets performance. We guarantee total dedication, timely delivery and attention to detail, despite the project size. Call 905.671.1677 if you are looking for laser welding and metal fabrication in Toronto and the GTA.

FAQs

What materials can be cut using metal laser cutting?

Metal laser cutting works on a wide range of materials, including stainless steel, aluminum, brass, copper, and mild steel.

Is laser cutting suitable for both small and large production runs?

Yes. Laser cutting offers flexibility for one-off prototypes, mid-sized batches, or full-scale production with consistent quality. Metal manufacturing leaders like Metal Tronics Inc. provide all sorts of services.

How accurate is metal laser cutting compared to traditional methods?

Extremely accurate. Tolerances can be within ±0.1 mm, providing superior precision and finish compared to mechanical or plasma cutting.